Manufacturing and Production

Streamline your entire manufacturing process from production planning and scheduling, through sequencing and execution, to monitoring and analysis, and improve efficiency along your entire value chain.

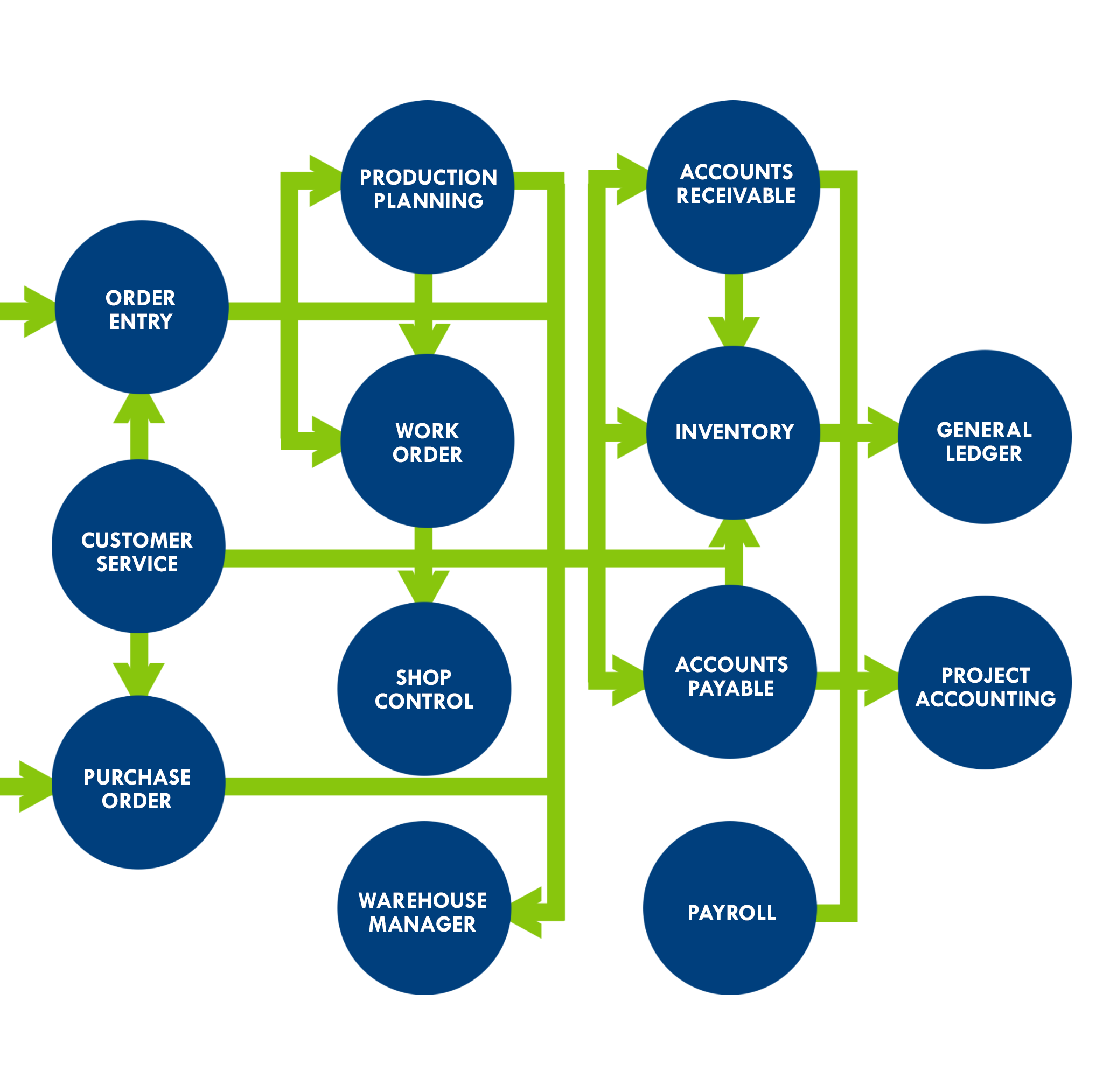

Helix ERP is designed to ease manufacturing systems management.

Manufacturing and Production Module Outline:

- Work Orders

- Production Entry

- Shop Control

- Project Accounting

- Shipping and Receiving

Work Orders

Work Orders is designed for manufacturing firms that require work order processing, component allocation, routing and Material Requirement Planning (MRP) features. Work Orders can be automatically generated from sales order requirements, inventory shortages, or inventory forecast requirements. By defining work centers and operation steps, users can create flexible labor routes.

Production Entry

Production Entry is designed for companies that need bill of materials, sales kit, configuration or back flush processing, but don’t require the allocation of BOM components. It supports unlimited levels of bill materials and real-time costing from Inventory Module. Modular and variable BOM types are available to handle product configuration issues with speed and flexibility, as well as maintaining fewer BOMs.

Shop Control

Shop Control provides shop floor capacity scheduling, what-if planning capabilities, and WIP tracking for production managers who require Manufacturing Resource Planning (MRPII). It imports open work orders with define routes, identifies bottlenecks, and calculates work order completion dates. What-if plan orders can be created to view resource requirements without affecting real-time purchasing decisions.

Project Accounting

Project Accounting provides a budget and costing tool for project accounting and job cost management. Its design allows up to four levels of cost tracking with project, phases, category, and cost-type definition. The job account mask supports the optional use of phrases and/or categories, and cost-types are user-definable.