Supply Chain Management

Helix Supply Chain Management (SCM) is a full suite of enterprise application capabilities—including purchase management, sourcing and procurement, inventory management, advanced material management, shipping and receiving, and warehouse management—and is complemented by forecasting, order management, and analytics capabilities. Combined, you have the solution you need to meet—and even exceed—customer expectations in today’s increasingly global market place.

A highly effective supply chain is critical to the success of your strategic growth initiatives. Top-performing manufacturers are empowering supply chain processes with innovative technology that is best-fit for unique operational needs, easy to use, and informed by industry best practices. Drive out costs, increase velocity, and enhance your customer experience with a strong supply chain that is ready for the future.

Helix SCM provides effective coordination from initial raw materials to the ultimate delivery of the finished product, transforming your supply chain into a results-driven value chain.

Supply Chain Management Module Outline:

- Purchase Management

- Order Management

- Inventory Management

- Transport, Manifesting and Freight Management

- Shipping and Receiving

Purchase Management

Purchase Management handles purchase order writing and the tracking of supplier performance to optimize results and improve negotiations. Multiple detailed line items indicate planned receipts to inventory or a job, direct receipts to a sales order, or direct receipts to a manufacturing job, although their destination may be changed at the time of actual receipt entry. Purchase order receipt processing updates suggested supplier and detailed purchase history files, which provides a continual reference to aid in making purchasing decisions. With Purchase Management, you can reduce inventory levels, improve on-time deliveries, enhance your cash flow, and increase your profit levels. Purchase Management capabilities include:

- Automated purchasing tools

- Supplier cross-referencing

- Supplier approval capability

- Mass purchase order receipt

- Multiple location receipts

- Part master price breaks

- Purchase requisition

- Purchase history

- Purchase order tracker

- Supplier tracker

Requisition Management

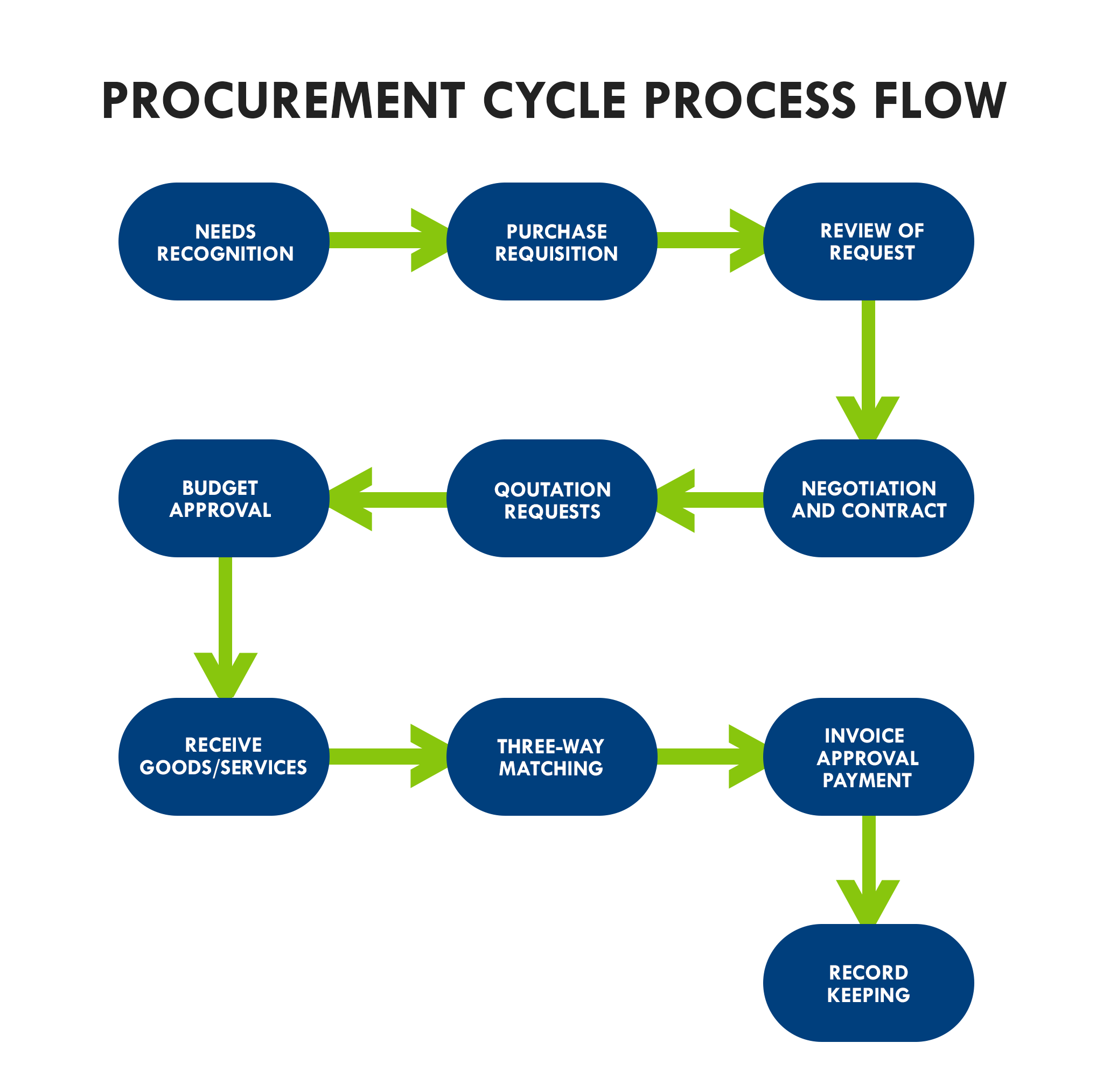

High-performing supply chains maintain a budget and control over items requisitioned for each stocking location for greater efficiency. Requisition Management enables organizations to gain visibility and regulate procurement spending by providing an online workflow and purchase requisition tool. It gains information on spending to supports negotiation of bulk purchase discounts from suppliers, assigns preferred suppliers for products, sets the right spend limits for individuals, and assigns the chain of authority for approving purchase orders.

Purchase Contracts

Helix Purchase Contracts is designed to automate the process of purchasing inventory items on a recurring basis—including the establishment of recurring delivery schedules. Contract line items can be assigned to purchase orders which automate your delivery schedules with delivery dates, prices, and corresponding quantities. Automatic requirement calculations— based on generated PO suggestions—are factored into delivery schedules, which you can adjust automatically to conform to supplier requirements or help with inventory control, production efficiency, and business expediency. Complete functionality includes part schedule maintenance for establishing the combination of part, plant, and calendar that makes up the part schedule, as well as periodicity code maintenance to establish the rules and terms under which orders periodically arrive from suppliers.

Supplier Connect

Strengthen your competitiveness by offering customers and business partners the ability to interact with your brand online. Supplier Connect is a supply-chain-focused feature of Helix Commerce Connect—a complete, connected, and customer-proven business solution for modern digital commerce and omni-channel enablement commerce. By providing the means for the customer and supplier self-service on a whole range of inquiries—such as open orders, part information, and access to old invoices—Helix Commerce Connect eliminates the need for inquiries to come in via email, phone, or fax to significantly reduce the amount of time staff need to spend answering them. Supplier Connect is specifically tailored for suppliers to update their information via their own supplier portal, answer requests for information, and confirm changes to purchasing orders. It can deliver performance metrics and also allows user-defined fields to flexibly extend your data storage options and send custom messages between your online store-front and your centralized back-office. This not only provides for a more seamless relationship between you and your suppliers, but it also allows your business to react much more quickly and accurately to any change of circumstances with supply.

Supplier Relationship Management

Supplier Relationship Management (SRM) provides tools for buyers, procurement staff, and purchasing agents, to request quotes for raw materials or subcontract services from one or multiple suppliers. Request for quotes (RFQs) is generated with one or more lines, allowing you to evaluate the responses from suppliers to decide which businesses can provide your company with the quantities, price points, and delivery dates you need for your manufacturing and servicing business flow. Supplier RFQ responses automatically build or add to existing part price-break tables with current effectivity dates to be used in other Helix applications

Order Management

Order Management drives the Helix system. From the time an order is entered, its progress is tracked through final shipment, producing perfect order fulfilment on demand for maximum customer satisfaction. The Order Job Wizard generates appropriate jobs for new orders in a single step that enables the user to create, plan, schedule, and release jobs against multiple lines and multiple releases. Effectively manage orders with the ability to apply order-based discounts on an order value or product quantity basis. Optionally override and lock pricing. Check customer credit status online at quote entry, order entry, and shipment entry. Using blanket orders establish multiple releases (either firm or not firm) for each sales order line and pull parts directly from inventory. Optionally lock the order line quantity allowing new releases to decrement the final delivery quantity on the final delivery date, keeping the total line quantity in balance with the release. Simplify repeat orders with the Copy Order function including the ability to optionally build a new order from history or see previous orders and enter the quantity on the order form. Use Available-To-Promise to view running balances during order entry. Enter a quantity, and the system will find the earliest date that quantity will be available. Enter a date, and see how many parts are available on that day. Counter

Sales allow you to automate the pick-up, shipment, and generation of sales invoices for walk-in customers. Additional capabilities include:

- Tax calculations and fields are available at the sales order, line, and release levels.

- Application for payment may be required from a different customer than the customer order/receiving the goods or bill third-parties, such as a customer of your distributor.

- Manage sales commission calculations for direct and indirect sales teams. Allocate commission percentage over multiple sales entities per order line.

- Generate customer, product group, warehouse, and products specific pricing hierarchies, while matching the end-user currency. For global enterprises, company, plant, and warehouse pricing offers flexibility in pricing products.

- Enter unlimited miscellaneous charges or credits on each order header or order line. These charges will then print on the order and carry over to invoicing.

- Link sales orders to Projects.

Sales Kits

Flexibility in selling items in kits includes configured item kits, optional price rollup and item substitution, mandatory ship complete, and optional printing of kit components on the packing slip and invoice. Use the answers from the kit master to “on the fly” configure individual kit components, automating kit instructions for features like style, color, and size. Configure a Kit within a Kit functionality support the ability to define multilevel configured sales kits that include non-stock components generated on a job or purchased direct for the kit, alongside stocked components.

Up-Sell, Cross-Sell, and Down-Sell

Improve order accuracy and ability to enhance sales with Up-sell, Cross-sell, and Down-sell capabilities. At the time of sales order entry, users are prompted with suggestions for “Upgrades,“ “Downgrades,“ “Substitutes,“ and “Complements.“ Whether substituting the original part with an upgrade or downgrade or adding complementary products; improved customer satisfaction alongside enhanced sales is the return.

Capable-To-Promise

Provide accurate, real-time delivery dates to customers when using Advanced Planning and Scheduling (APS). Furnish a realistic promise date to your customer by finding out how a quote would fit into your current schedule. For multilevel structured products, Capable-To-Promise can be configured to create the sublevel assembly structures in addition to the top-level assembly.

Fulfilment and Allocation Processing

Use the Fulfilment Workbench for allocation or reservation and distribution processing, and plan for sales, transfers and job order types. Various fulfilment techniques, such as pick and pack, console-driven, and pre-pack processes may be performed through the use of templates to automate the fulfilment process. Hard allocation to finite level, versus reservations processing, may be launched directly from the order, line, and release areas as well. In conjunction with the fulfilment process, cross-docking provides the ability to directly link future inbound supply of items from purchase orders or jobs directly to demand from sales orders, transfer orders, or jobs. When the cross-docked items are received, they are immediately directed to the demand they are linked to, minimizing the time and task to fulfil the order or job.

Order Shipment Parameters

With Order Management, all orders and change orders will be effectively managed online, perfecting the order-to-delivery process for maximum customer satisfaction. Set up the appropriate shipping parameters including the ability to manage:

- Track multiple ship-to addresses per order release.

- Ship an order from multiple plants and multiple warehouses.

- Do a one-time shipment to an address in Order Entry.

- Drop Ship and Buy to Order provides the ability from within a sales order to define a part as being “Buy-to-Order. This may or may not be defined as a drop-ship item. In both cases, the purchase order will be linked to the sales order directly.

- Automatically create backorders for lines shipped incomplete. Flexibility enables customer-specific backorder parameters for complete order lines or complete orders to be set.

Order Monitoring

Use order tracker to see a summarized view of the order, drill down on selected items to see greater details (e.g. lines, releases, shipments, charges, bookings, audit, and payment information). Monitor and track changes to orders using Social Enterprise. Easily subscribe to notifications about changes to orders without building Business Process Management (BPM) controls. View a summary of all the changes to the order in an activity stream inside or outside Helix ERP or receive social media style updates via Email or directly in your browser.

EDI/Demand Management

Today, all suppliers large and small are facing increased expectations from their customers to have systems in place for immediate response to changes in their demand such as forecast and shipping schedule changes. Helix EDI/Demand Management secures your competitive edge by incorporating electronic data interchange (EDI) with demand scheduling. The EDI/Demand Management framework leverages the SOA business architecture of Helix ERP and deep industry experience in EDI to lower the cost of EDI deployment. The framework provides full flexibility and control for setting up customer contracts and handling their schedules once inside the Helix ERP system, whether entered manually in Demand Management or contained in EDI messages. This helps your company reduce lead time and effort for planning and procurement, thus enabling you to respond on the production floor faster. A wide range of EDI implementation choices are available to match your company’s needs, making it possible to preserve much of your investment in EDI setup and existing staff.

Demand Management

A component of the embedded EDI/ Demand Management module, Demand Management starts with a “contract” set up per customer with such agreed-upon parameters as pricing, initial demand schedule, and contract end date. The contract is then linked to incoming purchase orders, forecasts, and shipping schedules. These contracts can be managed, and schedules produced, automatically with set periodicities or schedule constraints that match each customer’s unique shipping needs. Additionally, as changes happen, the schedules can be updated, and changes matched to existing sales orders, which are then updated accordingly. You can use Demand Management without EDI, and if EDI is deployed, your customers’ electronic demand changes are brought in automatically for system review and acceptance into sales orders or forecasts in your Helix ERP system, according to parameters and tolerances you specify. This is especially important for companies doing business in automotive as well as other industries such as industrial, consumer products, retail, and aerospace and defense. Demand Management capabilities include:

- Demand Contract structure provides the ability to have many sales orders/ lines attached to the contract.

- Demand Entry Management Console supports one inbound purchase order at a time, or options can be tuned for more automated entry into the Helix ERP system.

- Establish demand settings per trading partner to include tolerances, such as for allowable time windows when schedule lines can be added or deleted or changed, tolerances for price variations, parameters for matching changes against existing sales orders, and functions for reconciling shipped quantities between you and your trading partner. Automated Demand Management processing can be set to always process in spite of tolerance errors, process with warnings, or stop when an error is encountered.

- Use Demand Mass Review to manually match incoming forecast and shipping schedule changes to existing forecasts and sales order lines in the Helix ERP System. Configurable matching algorithms help to speed up the matching process.

- Manually generate sales order release schedules based on defaulted customer periodicity (interval setup) and release quantity. Automatically close rejected schedules from the customer record.

- Review balances as well as proposed quantity of proposed schedule.

- Manage and reconcile the cumulative shipped quantity. Validate cumulative quantity discrepancies by customer and choose to “Stop” or “Warn” and then allow the received demand to be turned into a valid sales order—this feature includes Cumulative Variances Reporting. The Demand Reconciliation screen helps in the cumulative matching process with the ability to easily make reconciled quantity adjustments. Cumulative quantities are tracked at the order and shipment levels over the life of the contract.

- Schedule forecasted deliveries that can be utilized with MRP to predict demand for resources and provide guidance on pending demand for materials.

- Periodicity (Interval Setup) – Specify rules by plant or plant/supplier for automatic purchase schedule suggestions. Periodicity rules can be specified as Daily, Monthly Forward, Weekly Forward, and Nth Day of Week.

- Capable-to-Promise – Set up the system to review open contracts and capacity requirements for a product and automatically adjust the new demand requirements after reviewing against open contracts as well as available capacity.

- Support for Allowance and Charge Codes – Optionally receive and process allowances and miscellaneous charges within EDI transmissions from trading partners. Both flat amounts and percentage based charges are available.

- Automated Order Match Validation – Automatically cancel demand releases received that are not matched to a specific order release.

- Close and Process Schedules – Use a single step to automatically close and process all schedules within Demand Management.

- Contract Start and End – Manage contracts effectively with contract start and end date.

Inventory Management

Inventory Management provides the key functions necessary to update and maintain raw materials, work in process (WIP), finished goods inventory quantities, costs, and on-hand requirements. Issued inventory reduces quantities on hand, which are continually replenished through the processing of purchased or manufactured item receipts into inventory. Receipt processing provides a continual update of inventory average, FIFO, lot, or last costs for every item. A variety of screen inquiries provide management analysis of Materials Requirements Planning (MRP), shortage monitoring, reorder analysis, stock status, valuation, and critical items. Functionality also includes:

- Alternate parts maintenance

- Costing management

- Country of origin tracking

- Cycle counting

- Global trade standards

- Manufacturers part

- Part cross-referencing

- Part master price breaks

- Physical and perpetual inventory

- RoHS compliance

- Time-phased material inquiry/report

- Unit of measure definitions

Additional Inventory management tools include:

- Lot Tracking and Attributes – Improve supply chain efficiency with full visibility of parts by lot throughout your system. Record material received, keep traceable material on-hand, and maintain detailed usage information by lot with the option to auto-generate lot numbers based on part-specific rules. Additional lot attributes can also be stored for each part lot, which include Batch, Manufacture Lot, Heat Number, Manufacture Date, Expiration Date, Firmware Version, Cure Date, Best Before Date, etc.

- Serial Tracking – Serial tracking helps to ensure product traceability, allowing for greater control over parts within the facility. Comprehensive functionality ranges from no serial tracking to full serial traceability of each recorded move of a part and its components. Optionally, you can record serial numbers at the outbound stage only. This is particularly useful for companies that must record what serial numbers have been shipped to which customers and when, but have no need to undertake the overhead costs of recording serial numbers as inventory moves around the warehouse or internal production facilities.

- Customer-Managed Inventory – Lower business risk by enhancing control over customer-managed inventory that you store but never own. These items can be used in the production of products for a customer or shipped by you directly to your customer’s customer.

- Supplier-Managed Inventory – Helix SCM allows you to designate material purchased as inventory you are storing as consignment inventory from the supplier. You can also use these part quantities on jobs, and once you consume it, your company legally owns the items

Inventory Optimization

Inventory Optimization delivers cloud-based inventory policy decision support and the means to share, collaborate, and track the impact of your inventory planning policy. Reconcile holding costs, ordering costs, and stock-out costs in order to prescribe the inventory policy and service levels that can help you yield the total lowest cost. To determine the right plan for your organization, assign service-level constraints and targets, evaluate proposed policies, and perform “what if” scenarios. Share proposed policies and agree on a plan that best meets the company’s objectives. Helix Smart Inventory Optimization will automatically upload the optimal planning parameters back to Helix ERP, and works with a variety of replenishment policies including reordering point/order quantity, min./max., safety stock planning, and order up to levels.

Operational Analytics

Operational Analytics is a cloud-based reporting platform that provides a fast, easily understood, current perspective on the state of your inventory. It performs against critical metrics, actual supplier lead times, and opportunities to rebalance stocks across facilities to help uncover operational inefficiencies. Inventory analytics offers a 360-degree view of your inventory to identify value, stocking trends, overstocks, understocks, potential order cancellations, and root causes of inventory issues. Supplier analysis provides comprehensive insight into your suppliers by measuring historical performance and lead times, which allows you to rank suppliers and identify trends. Operational performance analysis helps you continuously improve your operation by measuring and reporting on key performance indicators (KPIs) such as service level and fill rate performance, time to ship, number of stock-out events, and more.

Advanced Material Management

Advanced Material Management (AMM) enables businesses to produce electronic requests for materials, dispatch those materials, and track inventory movements of all inventory—including raw materials and work in process. Using wireless terminals and bar-coding technology, you are able to track inventory in real-time with complete control and visibility of raw materials and work in process as it travels throughout the enterprise. Complete functionality includes:

- Bar coding on demand

- Material handler interface

- Material movement

- Order prioritization

- Sales order allocation

- Bar code tag scanning

- Handheld capability

Package Control

Package Control functionality allows you to track, manage, or transact a group of items via a unique identifier. Track any item from receipt into a site, the movement of an item throughout the site, and eventually the shipment of that item to the customer. Also supporting the inbound generation of tracker, Helix ERP allows you to reserve and allocate PCIDs for sales orders, issue material to jobs, produce IDs from jobs, and receive ID finished goods in inventory to complete processing transactions. Perform pick transactions, shipping transactions, and job receipt to inventory transactions—among others— against a unique tracker. These IDs have an associated set of predetermined or user-defined physical and controlling characteristics, which comprise the package itself (properties and contents) and the label. Each can have its own rules of control, process flow, and status to give you greater control and visibility into your supply chain.

Transport, Manifesting And Freight Management

Today’s customers have many different shipping options. Helix Manifest, a multi-carrier shipping software for Helix ERP, streamlines domestic and international shipping processes to help you meet your customers’ demands. From rate shopping at order entry to manifesting your domestic or international shipments, Helix Manifest communicates with various carriers and provides the information about that shipment back to Helix ERP. As part of the shipping function, Helix Manifest prints labels, bill of ladings, and export documents to be included with your shipment. Capabilities include:

- International shipments and documentation

- Multi-account support

- Electronic Export Information (EEI) submittal and retrieval processing

- Configurable handling fees

- Automated hazmat paperwork

- Rate shopping

- Routing guide and best way

- Automated blind shipping

- Print or email return labels

- Order consolidations

Shipping And Receiving

The Shipping and Receiving module is designed to promote increased efficiency and accuracy by allowing you to perform and track all activity relating to shipments and receipts. This flexible module gives you the ability to auto-invoice in Accounts Receivable following customer shipment; print customizable bill of lading forms to your shipments; track container shipments and update the status and due dates of all purchase orders; track customer shipments; track landed costs against applicable parts, which reflects the true costs of materials, parts, or finished goods, and more. Complete functionality also includes:

- Mass ship

- Subcontract parts tracking

- Miscellaneous shipment tracking

- Miscellaneous receipts management

- Pack and ship/pack out processing

- Master pack tracking

- Phantom pack shipping

- Shipping performance reporting